Only released in EOL distros:

Package Summary

The phm_tools package

- Maintainer status: developed

- Maintainer: Hakan GENCTURK <hakan.gencturk AT inovasyonmuhendislik DOT com>, Elcin ERDOGAN <elcin.erdogan AT inovasyonmuhendislik DOT com>

- Author:

- License: Apache 2.0

- Source: git https://github.com/inomuh/phm_tools.git (branch: master)

Contents

Prognostics and Health Management Tools Project

Nowadays, prognostics-aware systems are increasingly used in many systems and it is critical for sustaining autonomy. All engineering systems, especially robots, are not perfect. Absence of failures in a certain time is the perfect system and it is impossible practically. In all engineering works, we must try to predict or minimize/prevent failures in the system. Failures in the systems are generally unknown, so prediction of these failures and reliability of the system is made by prediction process. Reliability analysis is important for the improving the system performance, extending system lifetime, etc. Prognostic and Health Management (PHM) includes reliability, safety, predictive prognostic, fault detection / isolation, advanced diagnosis, component lifecycle tracking, health reporting and information management, etc.

Reliability generally shows how successful a system is in performing its intended function. In order to increase the system performance, intensive studies are carried out on reliability models and analytical tools. It is true that the consequences of unreliability in engineering can be very costly and often tragic. In a changing world, reliability becomes more important to ensure that systems operate with high performance and gain functionality. Reliability engineering is applied in many fields such as defense industry, robotics industry, aerospace industry etc. The current generation of mobile robots have poor reliability. In order to design more reliable robots, we need analytical tools for predicting robot failure.

This study proposes Prognostic and Health Management (PHM) tool infrastructure using a model-based methodology for robotic systems. The main objective of this study is “Development of the General Prognostic and Health Management Tool” for ROS. The scope of this guide is processes and methodologies for conducting hazard rate of equipment, reliability predictions for electronic and mechanical systems. A comprehensive and systematic study of the different reliability models and analytical tools for various systems are also given. Furthermore, reliability, remaining useful life (RUL), and the probability of task completion of the robot (PoTC) are estimated in this tool. In this report, reliability and PoTC of the system is calculated by using hazard rate of the mechanical and electrical components, configuration of the robot (series, parallel, etc.). Results show that system reliability depends on hazard rate of all components in the system, their configurations, usage time and some environmental conditions (temperature, load, humidity, etc.). PoTC is the task completion probability of the robot that depends on the calculated reliability and distance travelled along the task.

NOTE: You can access our article "Prognostic & Health Management (PHM) Tool for Robot Operating System (ROS)" published as dissemination activity of this project from this link.

Overview of PHM Tool

PHM Tool consists of 2 tabs. Different operations are performed on each tab in the PHM Tool. The operations performed on each tab are describebd in detail in this section.

Basically 2 different operations are performed in the PHM Tool:

- Robot Configuration

- System Analysis and Monitoring

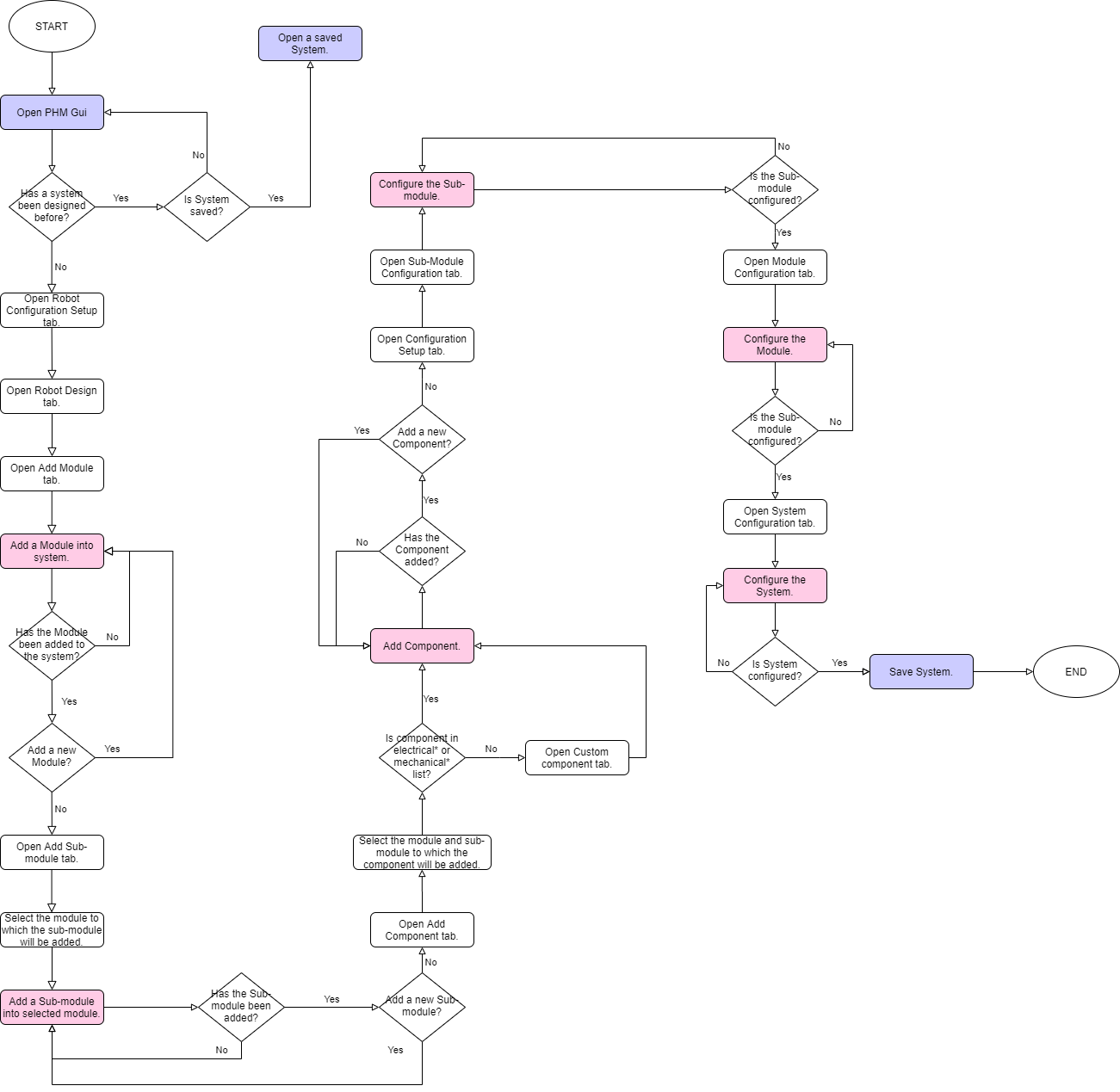

Robot configuration operations are performed in “Robot Configuration Setup” tab. The flowchart of the operations performed on the “Robot Configuration Setup” tab is shown in Figure 1.

Figure 1: Flowchart of "Robot Configuration Setup" tab

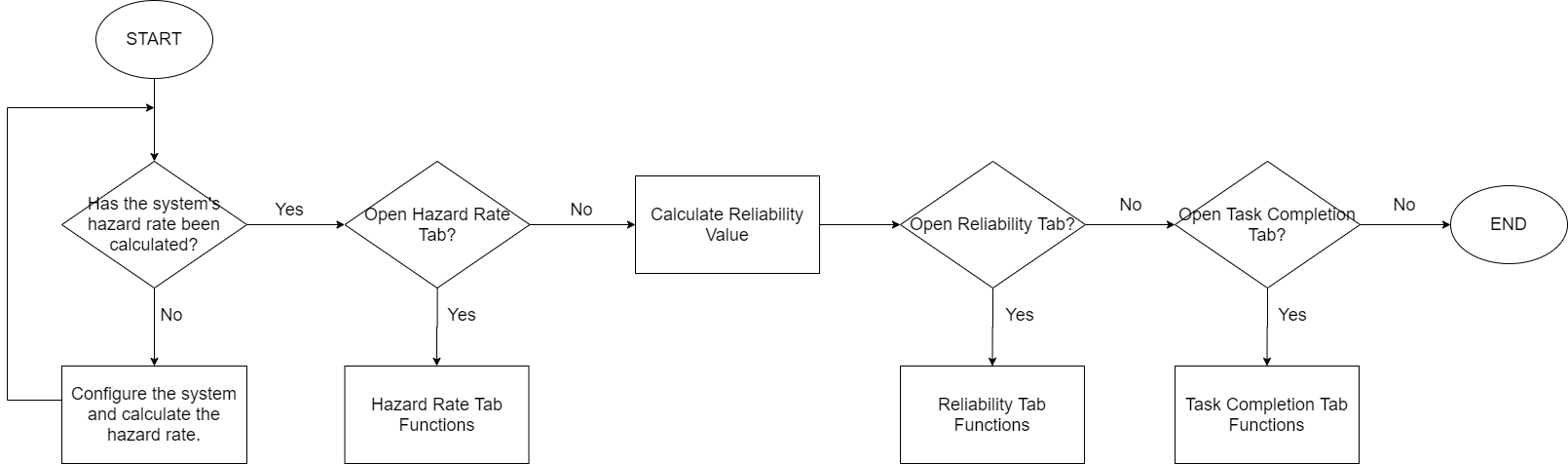

System analysis and monitoring operations are performed in “Monitoring and Analysis” tab. The flowchart of the operations performed on the “Monitoring and Analysis” tab is hown in Figure 2.

Figure 2: Flowchart of "Monitoring and Analysis" tab

How to Use Prognostics and Health Management Tool?

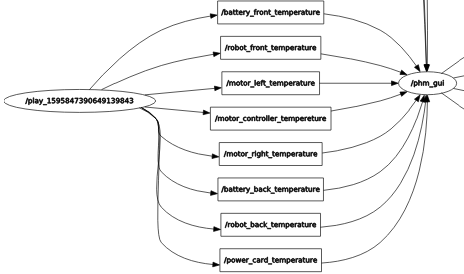

PHM tool is model-based user interface which the user creates his system using various mechanical and electrical equipments, but can also calculates the reliability, failure rate and probability of task completion (POTC) of the created system. In addition, the PHM Tool offers the user the ability to formulate his own components and add them to the system. PHM Tool can also work with a real robot. Datas from the sensors on the real robot are published via ROS topics. By subscribing to these topics in the PHM Tool, the system's failure rate, reliability and POTC values are calculated together with the data which is obtained from the sensors.

Failure Rate Calculation of System

PHM Tool is a modular interface. The user can create his own system using various electrical and mechanical equipments with this tool. Failure rate values of equipments are calculated using hazard rate calculation algorithms [1 - 4] in PHM Tool. Electrical and mechanical equipments in the PHM Tool are given in Table 1. Failure rate calculation formulas of all equipments in this table are included in references [1 - 4].

Electrical Equipments |

Mchanical Equipments |

Capacitor |

Spring |

Diode |

Gears |

Inductor |

Bearing |

Transistor |

Actuators |

Fuse |

Shafts |

Resistor |

Electric Motors |

Rotating Devices, Motors |

Mechanical Couplings |

Relays |

Battery |

Connectors, General |

|

Connectors, Sockets |

|

Quartz Crystals |

|

Table 1:Electrical and Mechanical Equipments in PHM Tool

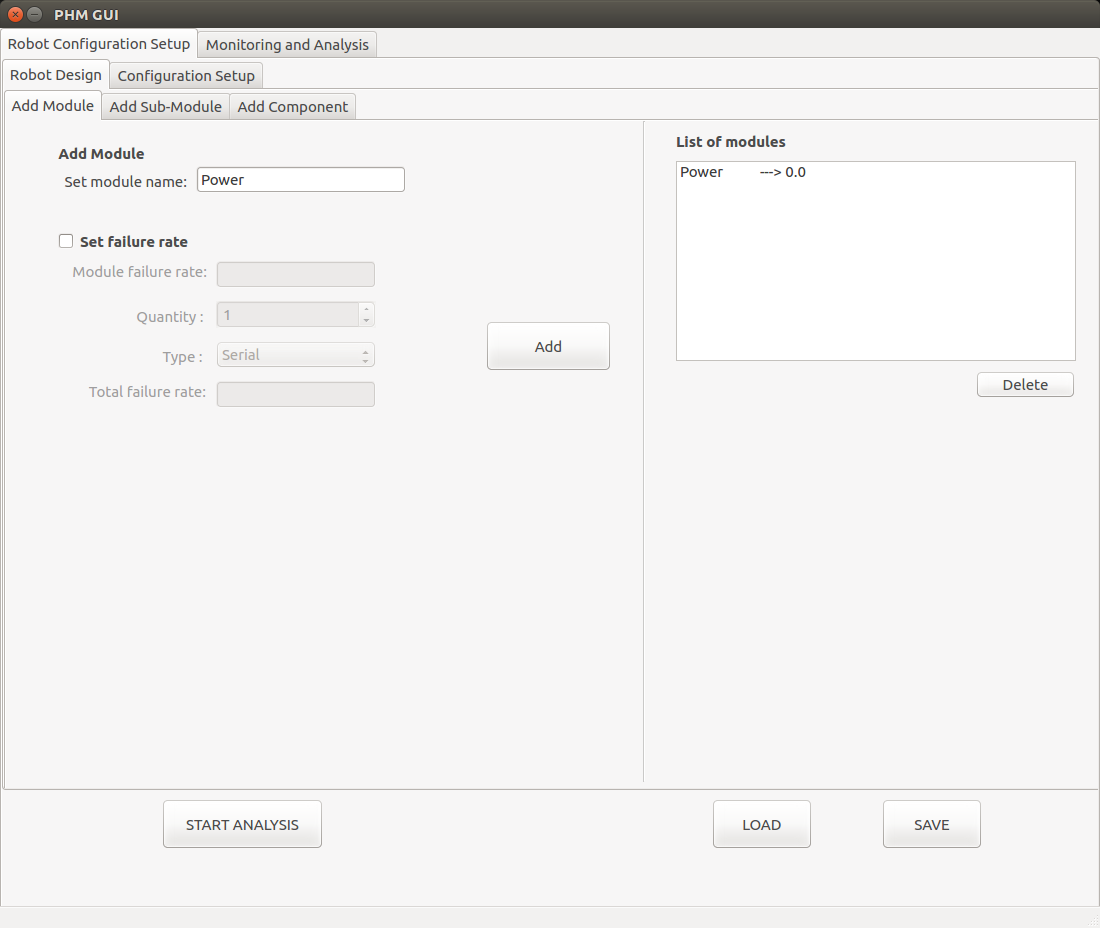

Since the PHM Tool is a model-based tool robot design must be done in tool. Therefore modules, sub-modules and components in the system must be added by user into the tool. Design of the system is done in the “Robot Design” tab of the PHM Tool (Figure 3).

Figure 3: Robot Design Tab in PHM Tool

Configuration of System

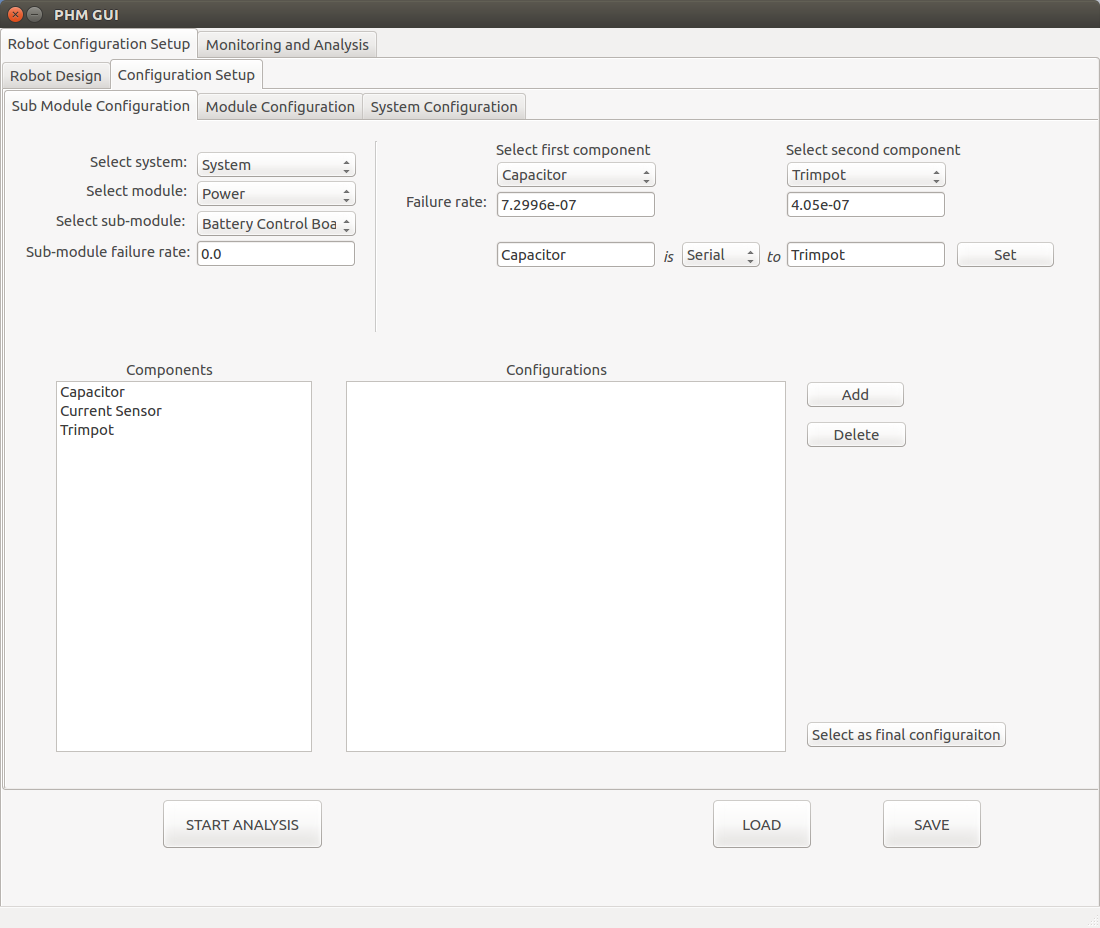

In PHM Tool, the reliability of the system has been calculated using the reliability estimation algorithms [5][6]. The reliability of the system is calculated by the physical arrangements of each item that creates the system. Thus, the effect of the failure rate value of each item on the system is modeled.

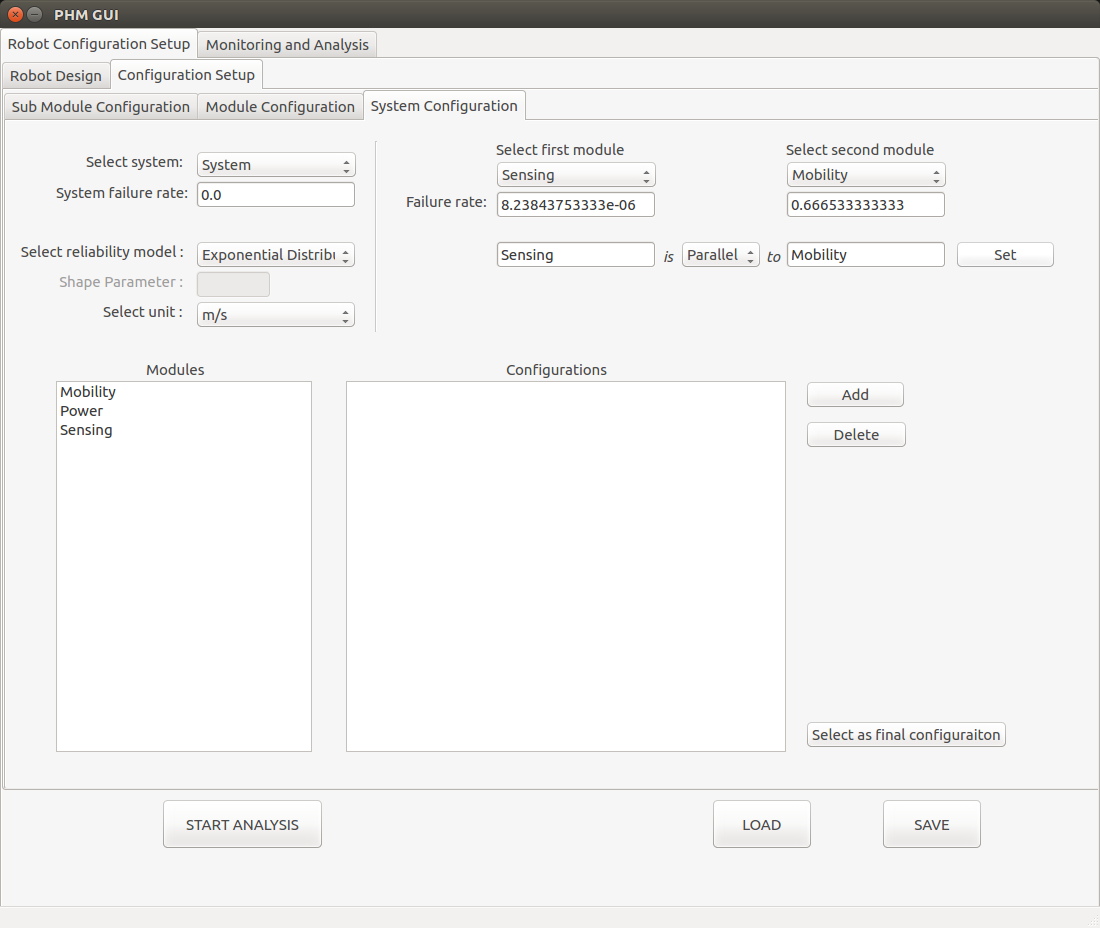

Figure 4: Configuration Setup tab in PHM Tool

Physical arrangements of the items in the system are made in 2 ways in the PHM Tool:

- Series

- Parallel

In a series configuration when the failure of any item results in a system failure. Accordingly, for the functional success of a series system, all items must operate successfully during the intended task period of the system.

In a parallel configuration, only failure of all items results give system failure. Accordingly, the success of only one item will be sufficient to guarantee the success of the system. Configuration of the system is done in “Configuration Setup” tab in PHM Tool (Figure 4). How to configure the system is explained in Section 3.3.2 of PHM Tool User Guide document.

Analysis of System

Accelerated life test (ALT) models given which is used in different conditions in order to calculate reliability analysis in this tool. The user can perform reliability analysis by choosing one of the following models:

- Exponential Distribution

- Curve Distribution

The following two formulas are used to calculate the reliability of the system and the probability of task completion (POTC):

The unit of time (t) in the formula used to calculate the reliability of the system should be hour or second. The unit of distance (d) in the formula used to calculate the POTC should be km or m. In PHM Tool the user has the opportunity to select any of these units (Figure 5). When the user chooses any of these units (m/s or km/h), reliability and POTC values are calculated according to the selected units.

Figure 5: ALT Models and unit selection in System Configuration tab

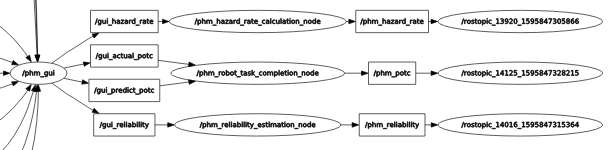

After the system is configured, the system must be started for analysis by clicking the “Start Analysis” button. There are 3 types of analysis available in PHM Tool:

- Hazard Rate Analysis

- Reliability Analysis

- Task Completion Analysis

How to analyse the system is explained in Section 3.4 of PHM Tool User Guide document.

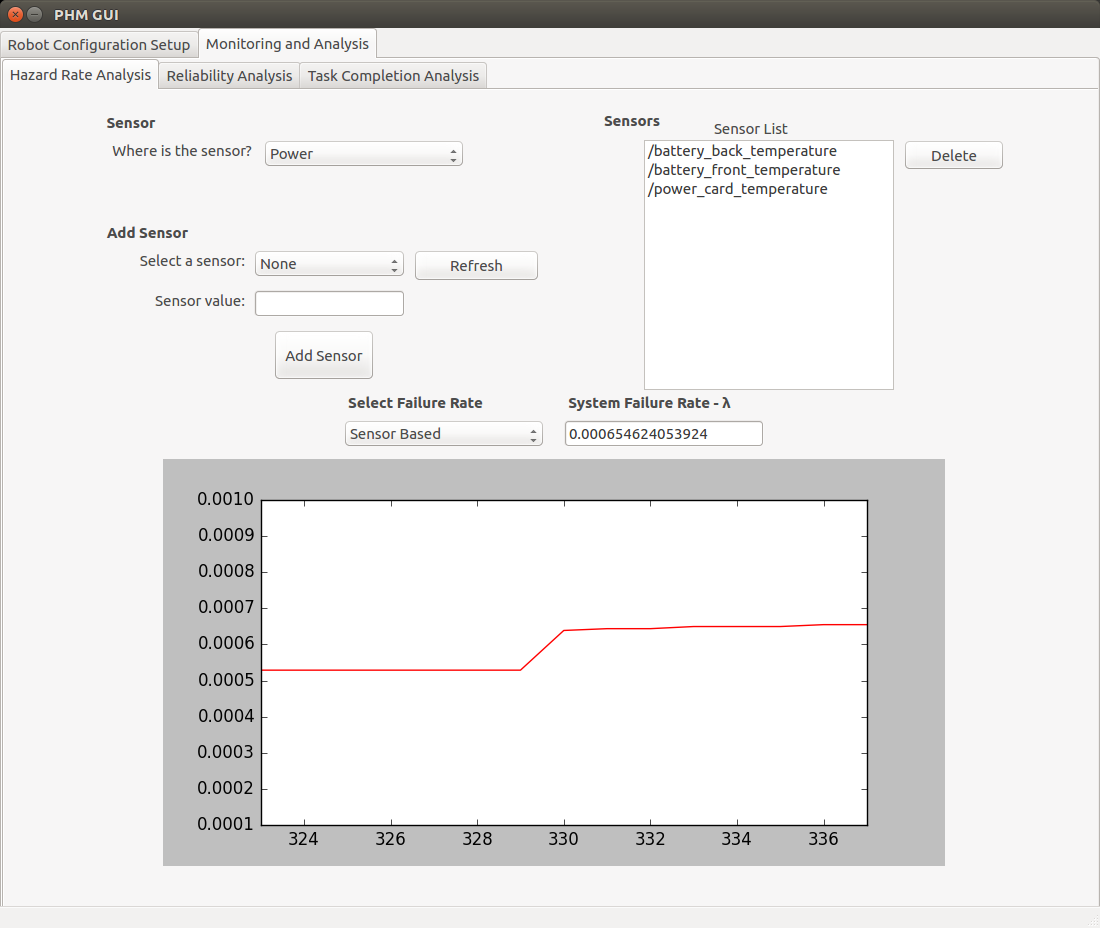

Hazard Rate and Reliability Analysis of System

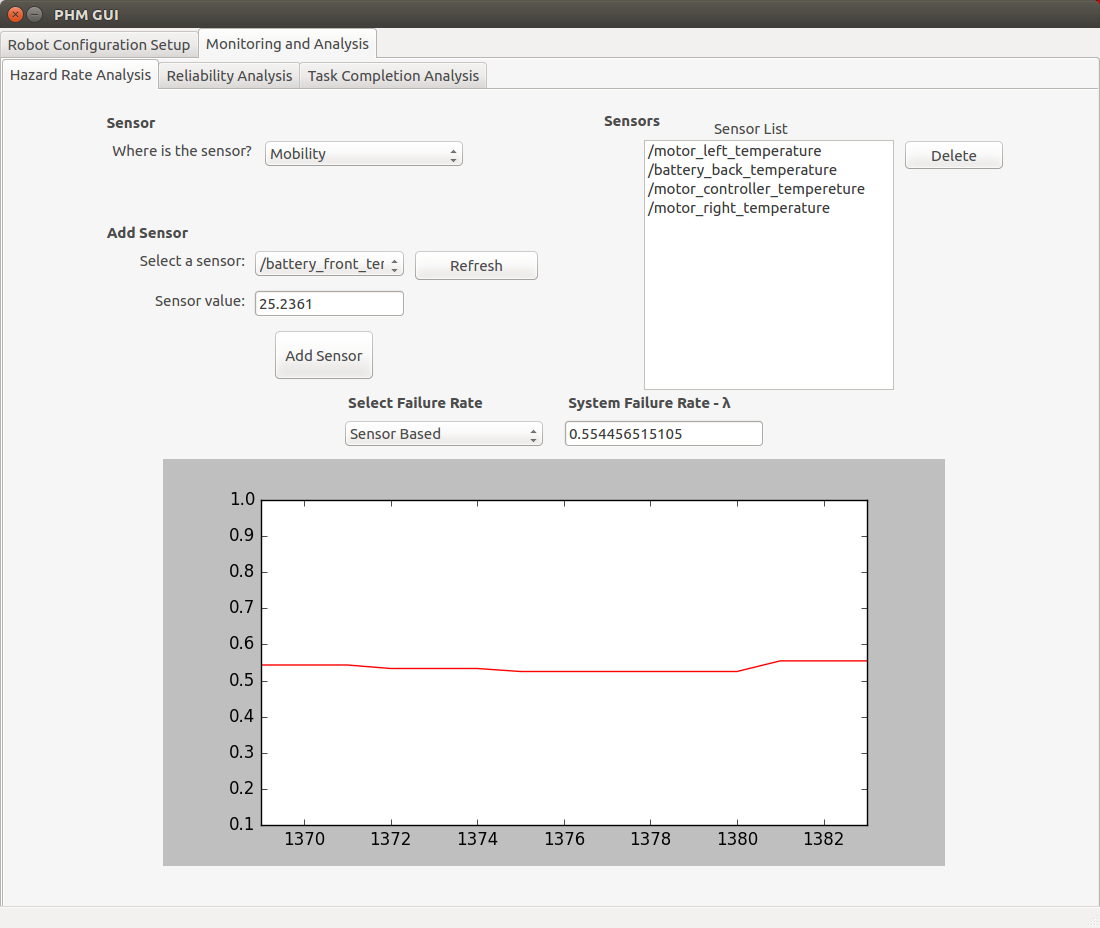

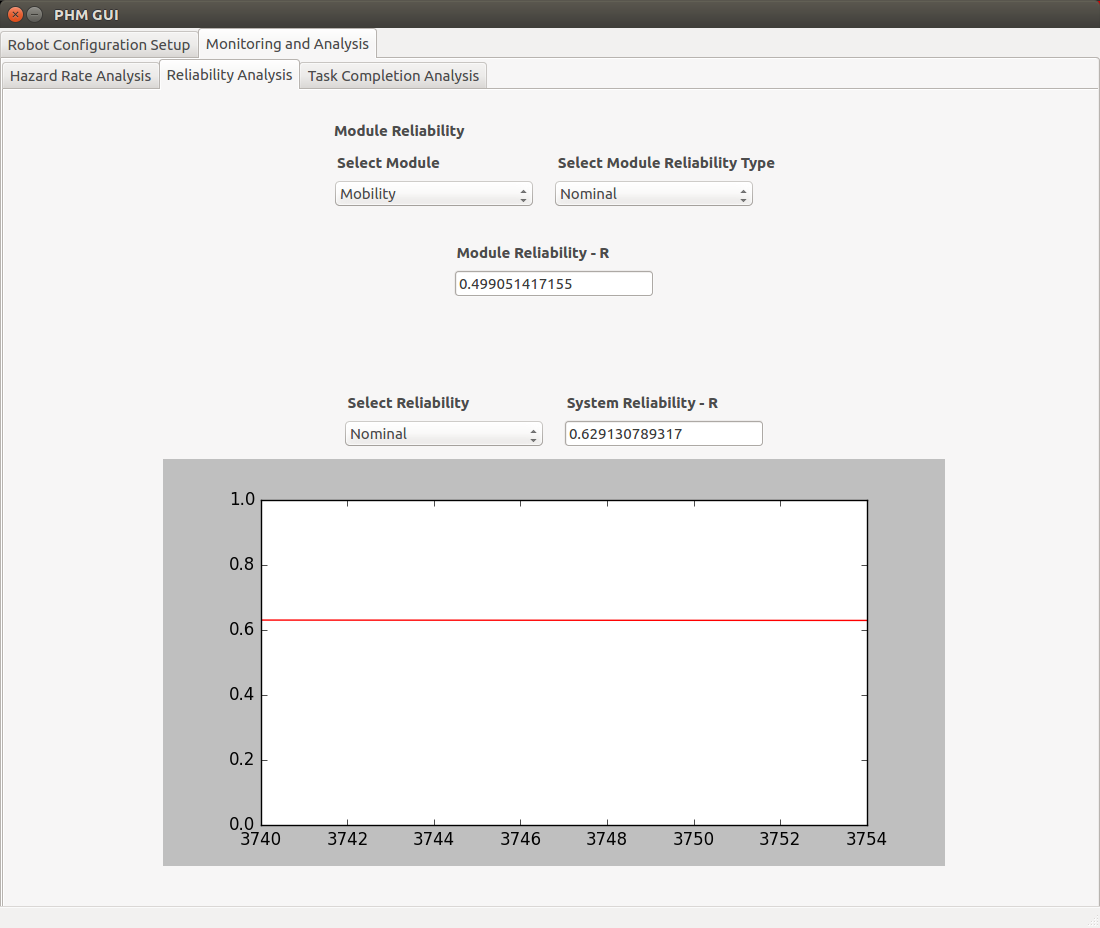

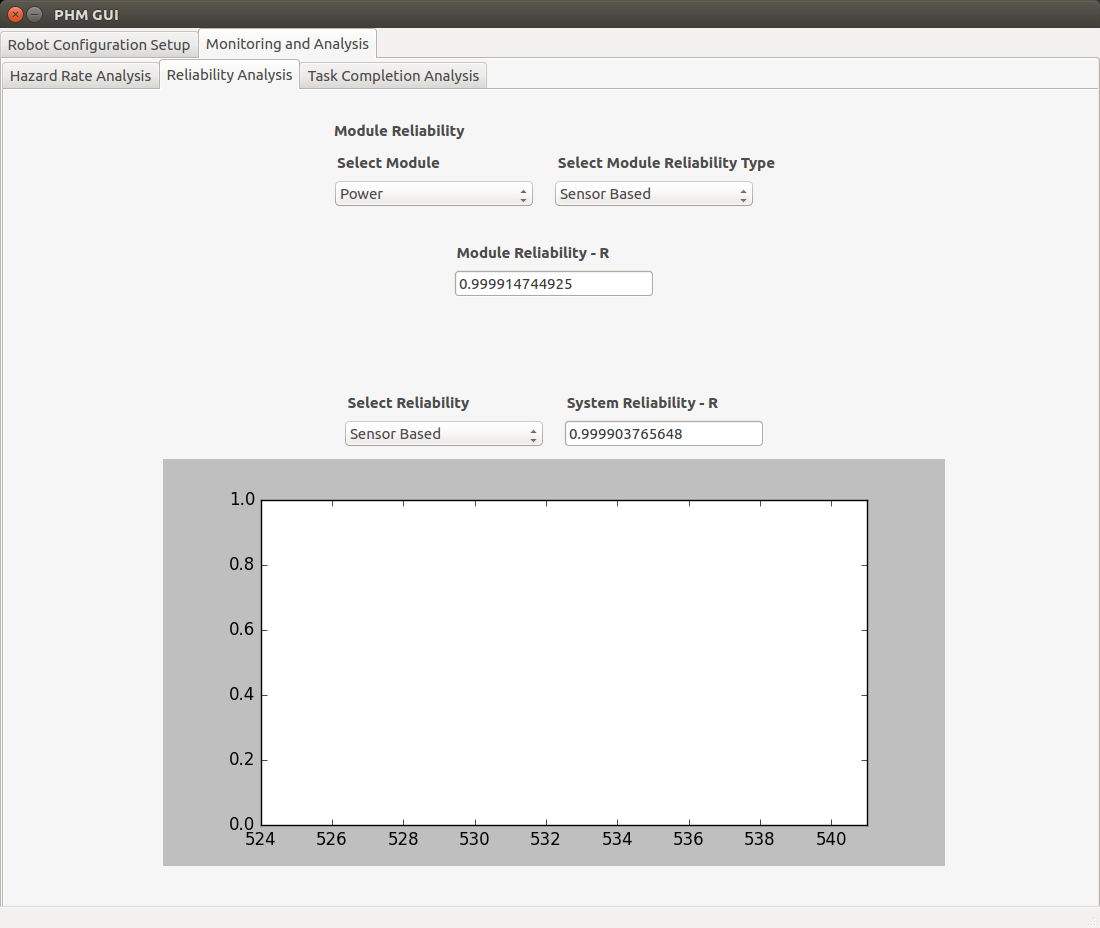

In the “Hazard Rate Analysis” and “Reliability Analysis” tabs (Figures 6 and 7), the graphs of the calculated hazard rate and reliability values are plotted in real time. At the same time, the user can add the sensor datas that are read from ROS topics in to the appropriate modules. Thus, besides the nominal values, a sensor-based hazard rate and reliability values should be calculated.

Nominal: The calculated hazard rate and reliability value of the system without adding any sensor.

Sensor based: Hazard rate and reliability values calculated by adding sensors to the modules in the system.

In PHM Tool, calculation of sensor based hazard rate and reliability values are done using temperature sensors only. These calculations’ formulas are located in FailureRateCalculation class. In order to make these calculations by adding other sensor types (load, humidity, etc.), the sensor type must be specified as input by the user in the interface. Since PHM Tool is open source software, the user can make the necessary arrangements in the interface and create the necessary functions in the FailureRateCalculation class.

Figure 6: Hazard Rate Analysis tab in PHM Tool

Figure 7: Reliability Analysis tab in PHM Tool

Task Completion Analysis of System

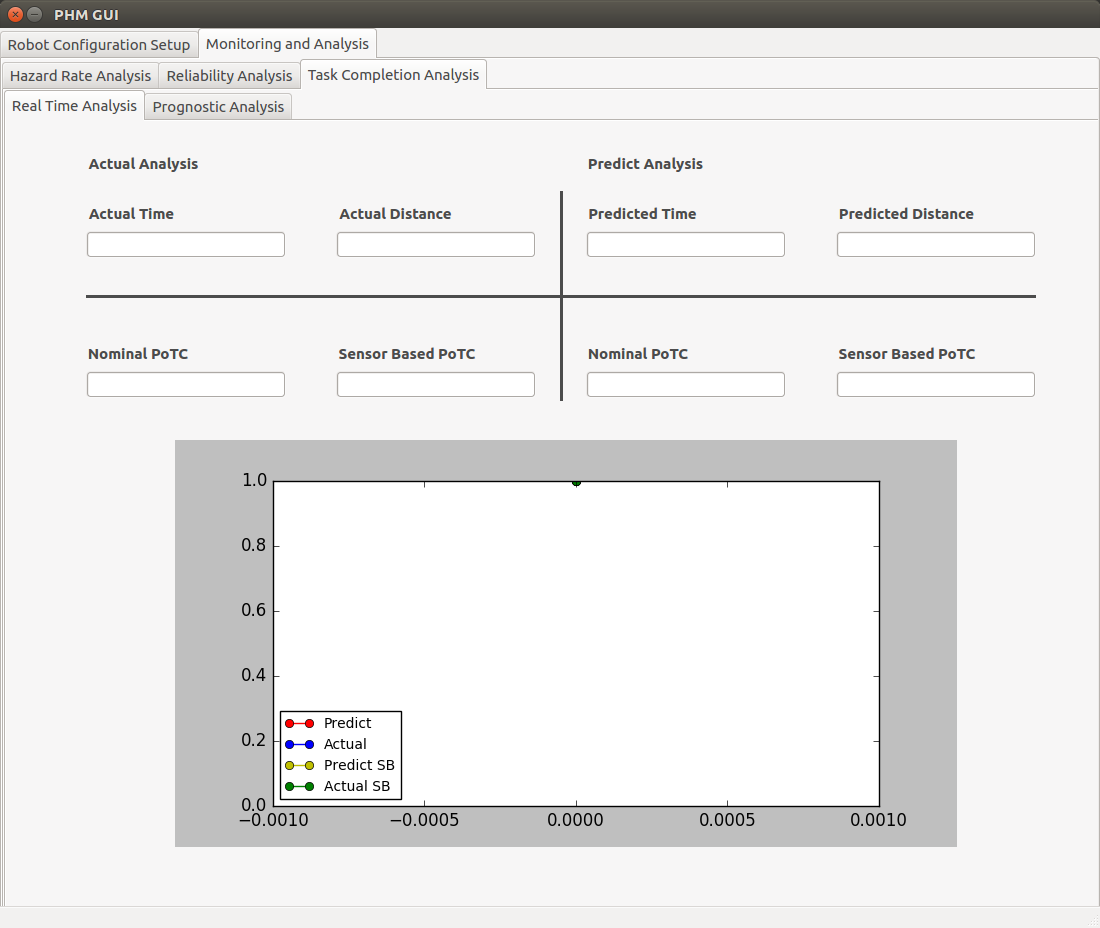

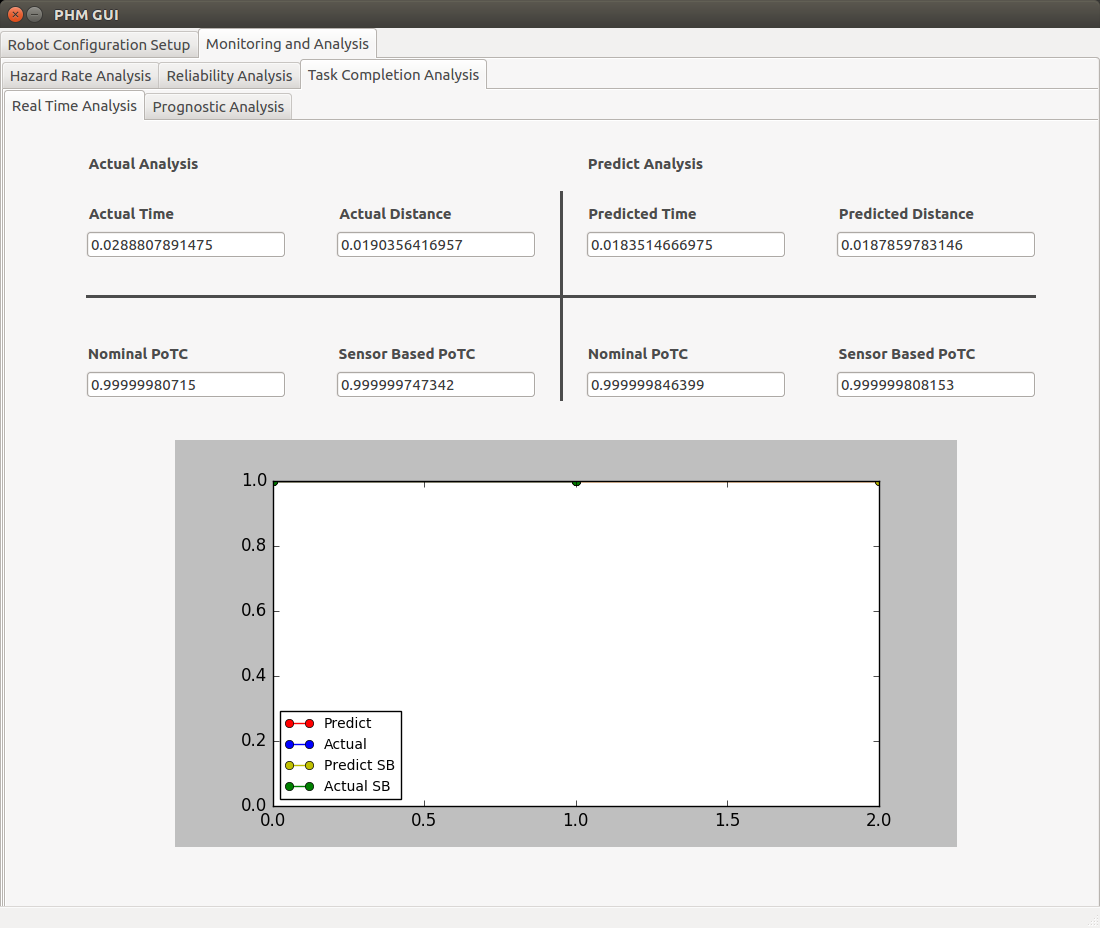

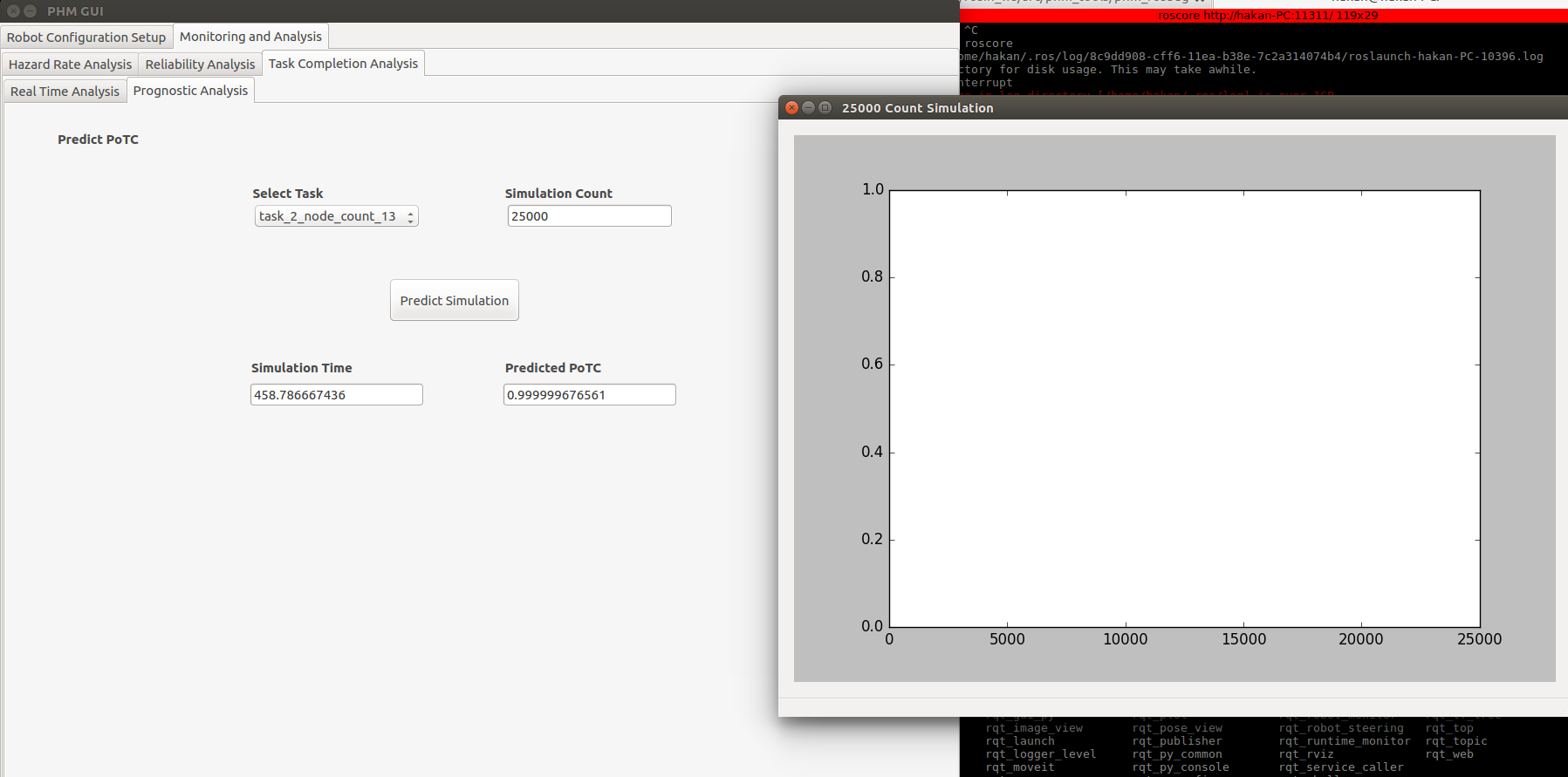

In the "Task Completion Analysis" tab (Figure 8), the calculated reliability value is used. In order to calculate the POTC value, the task sent for the mobile robot must come to PHM Tool. POTC value, total time and distance values are estimated before realizing the robot task by applying Predict analysis as soon as the task arrives. After estimation, besides the total time and distance values, nominal and sensor based POTC values are calculated and displayed on the interface and POTC values are added graphically. In addition, the incoming task can be used to calculate advanced simulation by adding it to the list of tasks in the "Prognostic Analysis" tab. The robot transmits distance and time values to PHM Tool after finishing the current task. POTC value is calculated as nominal and sensor based by applying actual analysis. The calculated POTC values are displayed in the interface along with the total time and distance values, and POTC values are added graphically.

Figure 8: Task Completion Analysis tab in PHM Tool

Use Case Scenario for PHM Tool

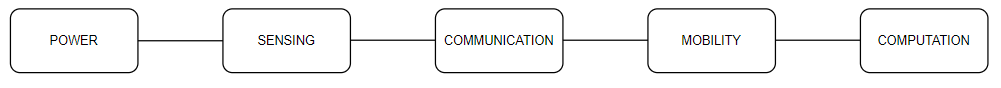

OTA Design and Configuration

Since PHM Tool is a modular tool, each of the modules, submodules and components in OTA must be added in this tool. OTA design is done by adding modules, submodules and components in PHM Tool.

OTA should be configured by making physical arrangements of these added parts according to each other. As a result of the design and configuration of OTA in the PHM Tool, the hazard rate and failure rate values of the system are calculated.

OTA Design

The modules, sub-modules, components on the OTA, their quantities and failure rate values calculated for one of them with the PHM Tool tool are shown in Tables 2, 3, 4, 5 and 6. OTA design is done in the "Robot Design" tab under the "Robot Configuration Setup" tab in the PHM Tool. The procedures for adding all the equipment in OTA to the PHM Tool are described in Section 3.1 in the PHM Tool Use Case document.

At the same time, the design processes for the OTA use case scenario of PHM Tool are explained in the video below.

Module |

Sub-module |

Component |

Quantities |

Failure Rates |

Power |

Battery |

- |

4 |

2,00E-08 |

|

Battery Control Board |

Capacitor |

28 |

9,36E-06 |

|

Thermistor |

9 |

7,33E-06 |

|

|

Diode |

16 |

6,25E-07 |

|

|

LED |

9 |

5,00E-06 |

|

|

Resistor |

26 |

1,33E-07 |

|

|

Trimpot |

3 |

2,42E-06 |

|

|

Step Down Switching Regulator |

7 |

3,96E-07 |

|

|

Terminal Blocks/Connector |

9 |

2,21E-06 |

|

|

Connector/Socket |

1 |

1,18E-07 |

|

|

Inductor |

7 |

5,80E-08 |

|

|

Current Sensor |

2 |

2,50E-07 |

|

|

Female Header |

1 |

1,90E-06 |

|

|

Low Level Control Unit: DSK-MD |

XT60 Socket |

4 |

7,53E-08 |

|

|

Zener Diode |

4 |

1,77E-07 |

|

|

Ultrafast Diode |

4 |

5,29E-07 |

|

|

Aluminum Capacitor |

4 |

1,40E-07 |

|

|

Micro USB Connector |

1 |

6,07E-07 |

|

|

16MHz Cryst. Osc. |

1 |

1,77E-06 |

|

|

32.768Khz Cryst. Osc. |

1 |

4,26E-07 |

|

|

Resistors |

65 |

4,99E-07 |

|

|

STM32F407VGT6 |

1 |

1,00E-08 |

|

|

Resettable Fuse |

2 |

2,30E-06 |

Table 2: Sub-modules and components list of Power module with failure rates

Module |

Sub-module |

Component |

Quantities |

Failure Rates |

Sensing |

SICK Laser Sensor |

- |

1 |

8,00E-08 |

|

IPS |

Antenna |

1 |

5,80E-07 |

|

|

Micro USB Connector |

1 |

6,07E-07 |

|

|

DW1000 Chip |

1 |

8,60E-08 |

|

|

Resistor |

5 |

4,46E-07 |

|

|

Capacitor |

5 |

9,36E-07 |

|

Camera |

- |

1 |

5,88E-09 |

Table 3: Sub-modules and components list of Sensing module with failure rates

Module |

Sub-module |

Component |

Quantities |

Failure Rates |

Communication |

Communicaton Card: DSK-M |

Resistor |

9 |

4,53E-07 |

|

Capacitor |

9 |

1,66E-07 |

|

|

25MHz Crystal Oscillator |

1 |

6,54E-06 |

|

|

16Mhz Crystal Oscillator |

1 |

5,90E-07 |

|

|

STM32F407VGT6 |

1 |

2,30E-07 |

|

|

SN65HVD230DR |

1 |

1,70E-07 |

|

|

Fuse |

4 |

8,00E-08 |

|

|

LAN8720A-CP |

1 |

5,90E-07 |

|

|

Micro USB Connector |

1 |

2,43E-06 |

|

|

Antenna |

- |

1 |

7,50E-07 |

Table 4: Sub-modules and components list of Communication module with failure rates

Module |

Sub-module |

Component |

Quantities |

Failure Rates |

Mobility |

Encoder |

- |

2 |

5,80E-06 |

|

Driver wheel |

- |

2 |

1,80E-07 |

|

Caster wheel |

- |

4 |

6,80E-06 |

|

DC Motor |

- |

2 |

8,04E-06 |

|

Bearing |

- |

4 |

3,61E-11 |

Table 5: Sub-modules and components list of Mobility module with failure rates

Module |

Sub-module |

Component |

Quantities |

Failure Rates |

Computation |

YSK-M: High Level Control Unit |

Inno-Box Industrial Box PC |

1 |

6,50E-08 |

|

YSK-G: Vision Control Unit |

NVIDIA JETSON TX2 |

1 |

5,00E-08 |

Table 6: Sub-modules and components list of Computation module with failure rates

OTA Configuration

After each equipment in the OTA is added in the "Robot Design" tab of the PHM Tool, the system must be configured in order to calculate the total failure rate and reliablity values of the system.

The configuration of the OTA is done in the "Configuration Setup" tab under the "Robot Configuration Setup" tab in the PHM Tool tool.

Configuration of the equipments in the OTA is included in section 3.2 of the PHM Tool Use Case document. At the same time, the configuration operations performed in the PHM Tool use case scenario for OTA are explained in the video below.

While configuring OTA, the following steps are followed in order:

Configuring components under each submodule: This section is explained in detail in Section 3.2.1 of the PHM Tool Use Case document.

Configuring submodules under each module: This section is explained in detail in Section 3.2.2 of the PHM Tool Use Case document.

Configuring the modules under the system (OTA): The configuration of the OTA is made as in the Figure 9. This section is explained in detail in section 3.2.3 of the PHM Tool Use Case document.

Figure 9: Configuration of OTA

Monitoring and Analysis of OTA

In the Monitoring and Analysis tab, the configured system in the “Robot Configuration Setup” tab is presented to the user in real time by calculating the hazard rate, reliability and POTC values according to the specified reliability model and unit. In addition, sensors can be added and the results are shown in real time.

Monitoring and Analysis is explained in detail in Section 4 of the PHM Tool Use Case document. At the same time, the processes under Monitoring and Analysis tab for the OTA use case scenario of PHM Tool are explained in the video below.

Figure 10: Added Sensors from Rosbag

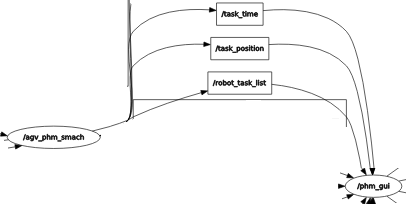

Figure 11: Architecture Between Phm Tools Nodes

Figure 12 Hazard Rate Analysis Tab

Figure 13 Reliability Analysis Tab

Figure 14 POTC Real Time Analysis Tab

Figure 15 POTC Prognostic Analysis Tab

Figure 16 Publishing Tasks from Smach to PHM Tools

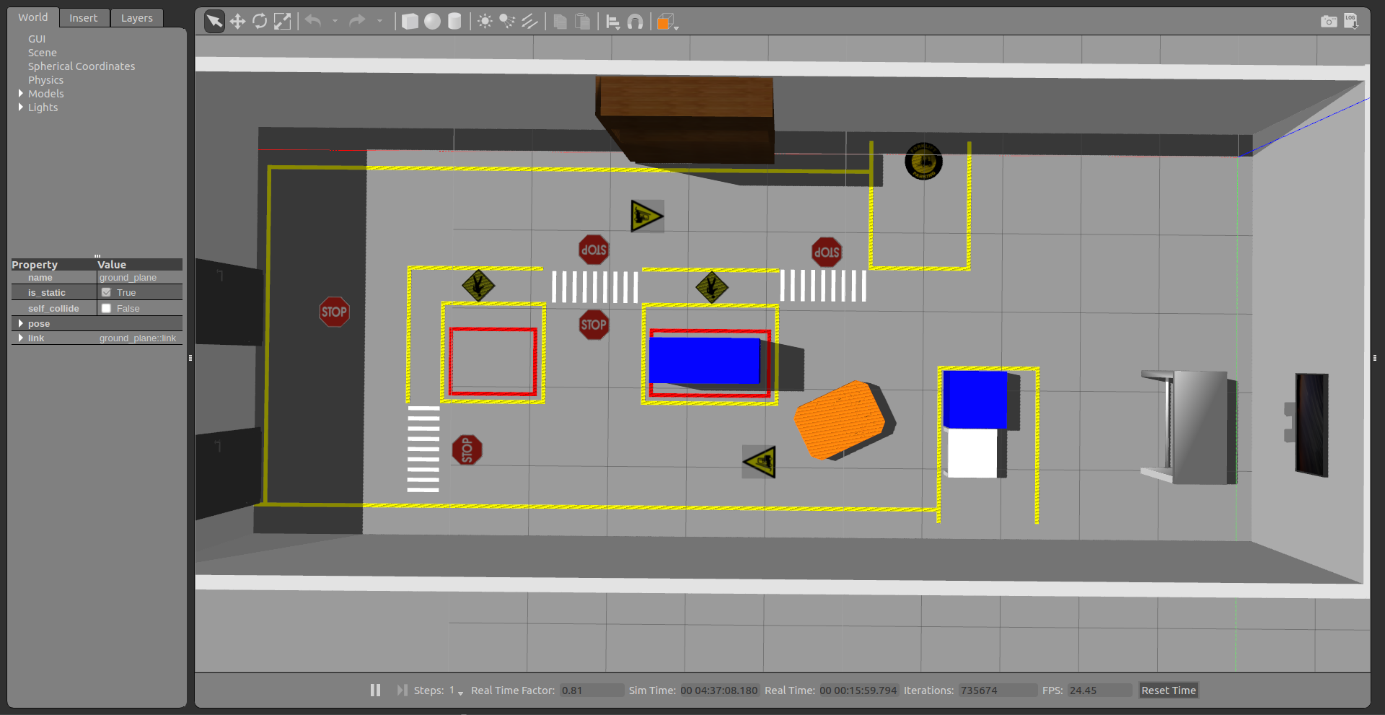

Figure 17 Gazebo

Report a Bug

Use GitHub to report bugs or submit feature requests. [View active issues]

Acknowledgements

Supported by ROSIN - ROS-Industrial Quality-Assured Robot Software Components.

More information: rosin-project.eu

|

This project has received funding from the European Union’s Horizon 2020 |

References

[1] Center, N. S. W. (1992). Handbook of reliability prediction procedures for mechanical equipment. Carderock Division, Naval Surface Warfare Center.

[2] H. Wayne Beaty and James L. Kirtley, Jr., Electric Motor Handbook, McGraw-Hill Book Company 1998.

[3] IEC 62380 Technical Committee. (2004). Reliability Data Handbook-Universal Model for Reliability Prediction of Electronics Components, PCBs and Equipment. IEC TR 62380.

[4] US Department of Defense. (1986). Military Handbook. Reliability Prediction of Electronic Equipment. US Department of Defense.

[5] Modarres, M., Kaminskiy, M. P., & Krivtsov, V. (2016). Reliability engineering and risk analysis: a practical guide. CRC press.

[6] IEEE Standard 1413.1‐2002. (2003). IEEE guide for selecting and using reliability predictions based on IEEE 1413.